Product name:

Product display

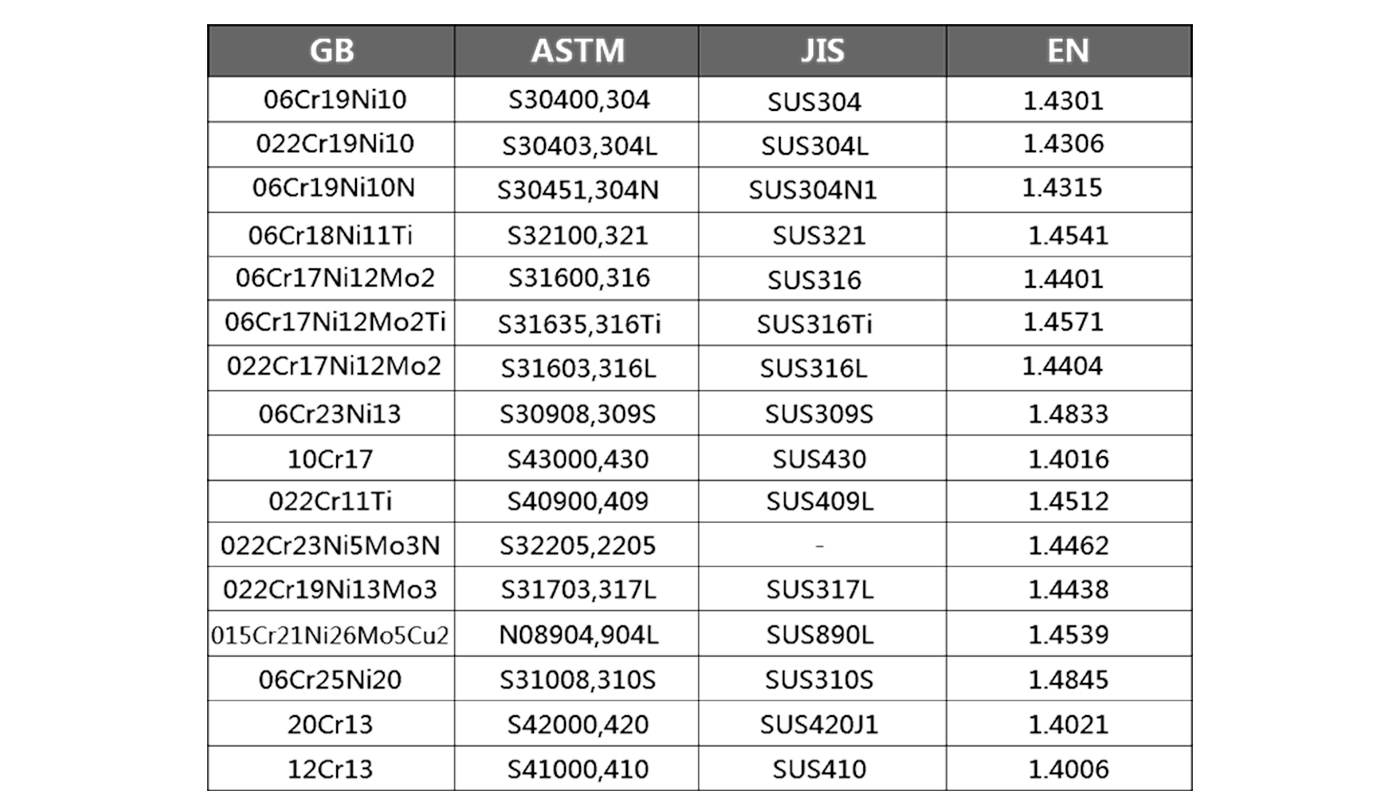

Product material

Our factory

Product packaging

PACKAGING

Excellent package: Anti-water paper and plastic film+covered by iron sheet+ strapped with min three strappingstrips+fixed on the iron or wooden pallets by strapping stripslt can effectively pratect products from corrosion andvarious climate changes during ocean transportation.

SHIPPING

We have long-term cooperation with many experiericed shipping companies, and we will find the most suitable transportation method for you.

Product application

Product parameters

Chemical Composition

Product parameters

1. 30% of the advance payment is reserved to support customers and third-party inspectors who fail to pass the acceptance inspection and receive a full refund of the advance payment

2. 30% of the advance payment is for stocking, and the remaining 70% can be paid through a letter of credit (LC)

3. Full weight, full weight, insufficient weight, and 10 times compensation can be signed into the contract. Honest cooperation and mutual profit in steel manufacturing for 15 years. We are committed to becoming your most professional steel supplier and your most trusted partner

Feel free to contact us

You can consult us at any time if you have any questions. You can email or call us at any time, and we will reply to you as soon as we receive your information.

لا تتردد في الاتصال بنا

إذا كان لديك أي أسئلة ، لا تتردد في الاتصال بنا . يمكنك دائما البريد الإلكتروني أو الاتصال بنا ، ونحن سوف الرد عليك في أقرب وقت ممكن بعد تلقي المعلومات الخاصة بك .